Brazil’s Leading Industrial Shredders — Trusted Worldwide

Bring the same high-throughput, low-maintenance technology to your operation — wherever you are.

Sustainable waste shredding solutions with international standards

Shredders widely known in the market for their robustness, reliability and especially for their ease of maintenance.

Join other market leaders and achieve the lowest cost per crushed ton in your company as well.

Find out how much it costs, per ton, to produce CDR on Jaguar equipment.

Low OPEX, higher OEE. This is how we will improve your operation. Our consultants will get you the best machine suitable to your specific need.

Medical Waste

Reduce the volume of medical waste and biological waste for sterilization or final disposal.

Municipal Solid Waste (MSW)

Bring new life to the municipal solid waste, by sorting recyclables, organics, and producing RDF/SRF alternative fuel.

Plastic Waste

Convert post-consumer plastics into reusable flakes for extrusion or moulding.

Organic Waste

Execute a selective sorting of paper, plastic, metal, and glass off the organic fraction and get cleans organics to biodigestion process.

End-of-life Tyres

Shredding of end of life tires upgrade then to a new lifecycle, by energy recovery or even full recycling, producing crumb rubber and “black gold”.

WEEE / E-scrap

Recover valuable materials such as ferrous, aluminium, ZORBA and PCB plates by shredding and sorting automated systems.

Trust in those who are a world reference and national leader

Robust Shredders Engineered for 24/7 Performance

Alligator™ Primary

Up to 330 t/h

4 – 8 in (100 – 200mm)

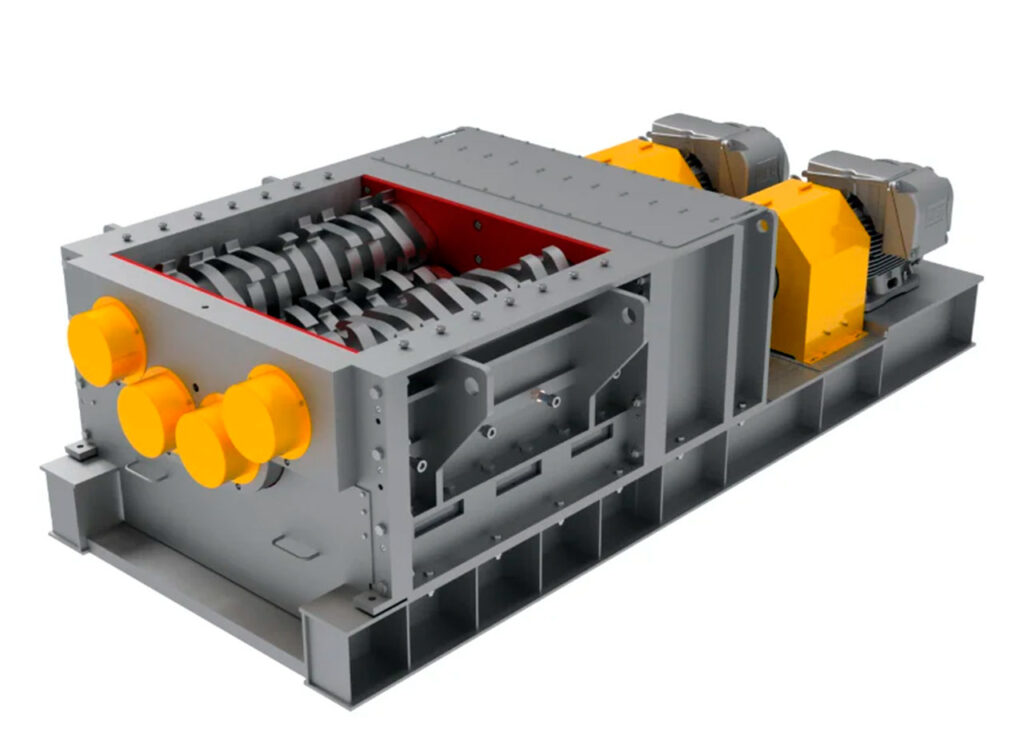

Jaguar Quad™ Secondary

Four-shaft rotary shear

Up to 15 t/h

0.6 – 4 in (15 – 100mm)

Raptor™ Fine

Single-shaft high-torque

Up to 25 t/h

1 – 4 in (25 – 100mm)

The leaders of Waste management in Brazil trust Jaguar.

"Jaguar`s four-shaft shredder reduced our disposal cost by 42%"

- Global Comment Producer